About our

Selink VietNam

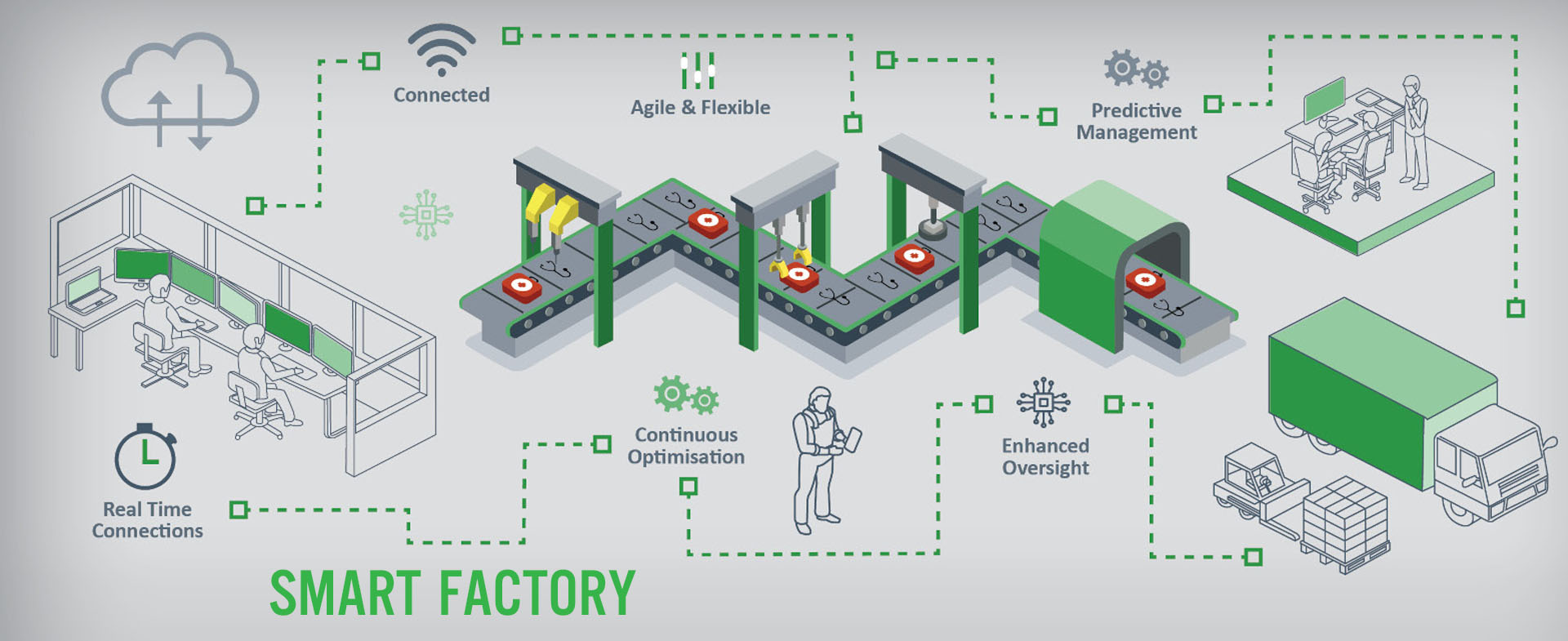

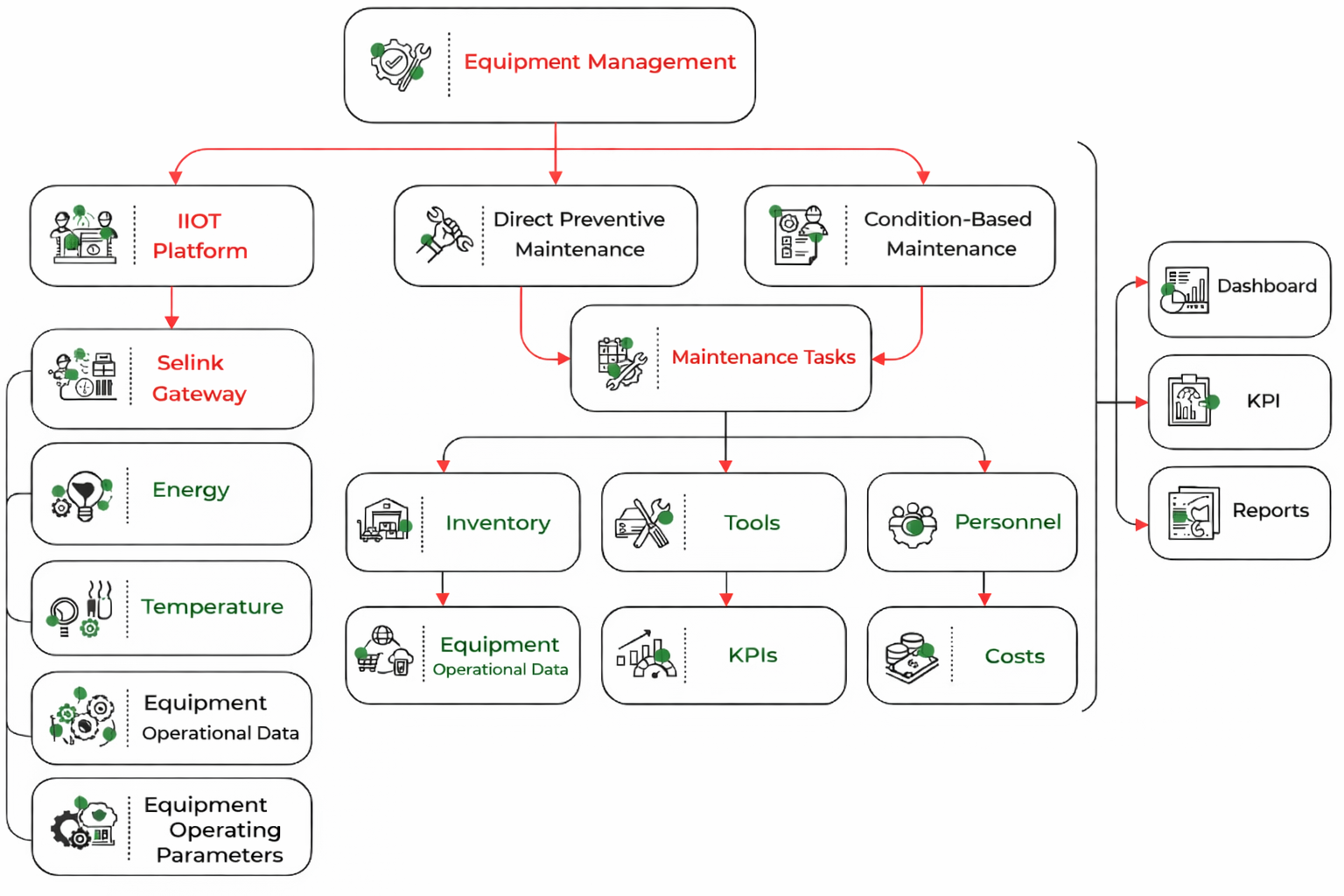

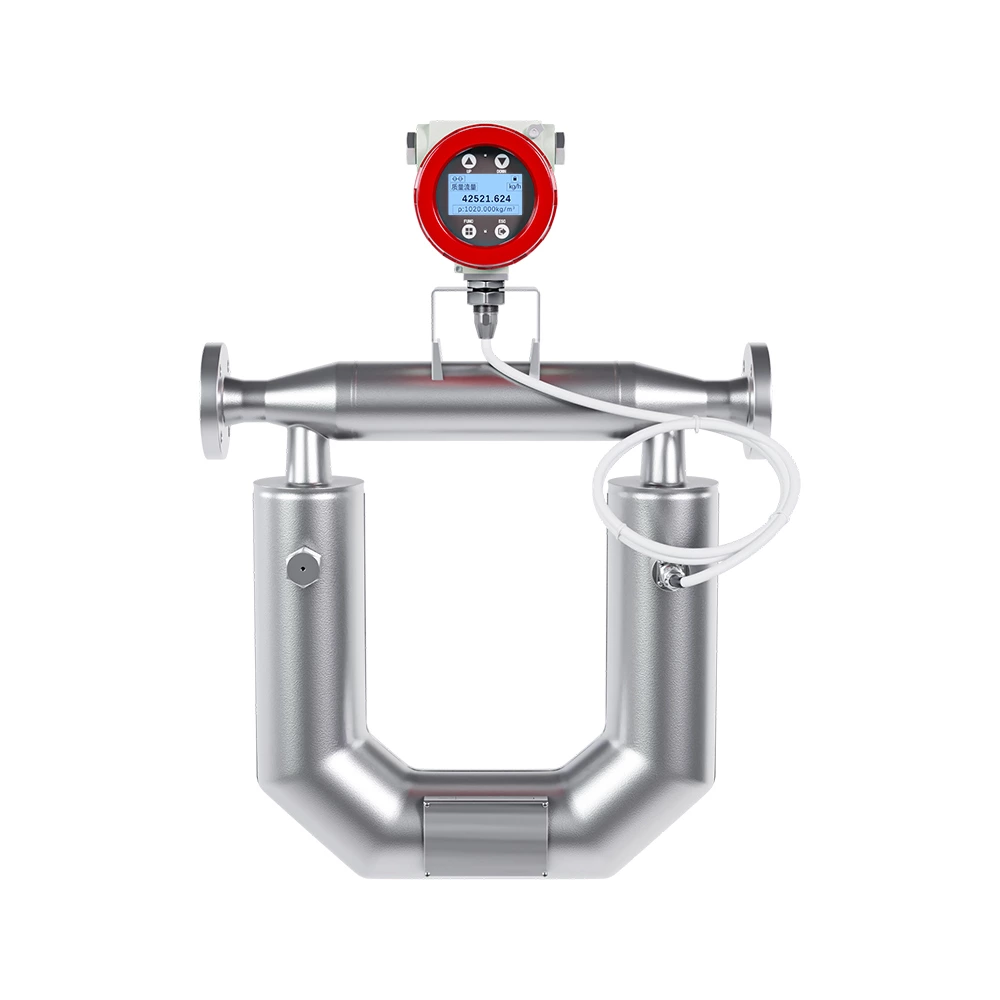

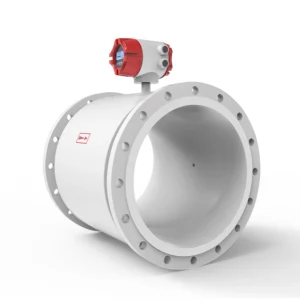

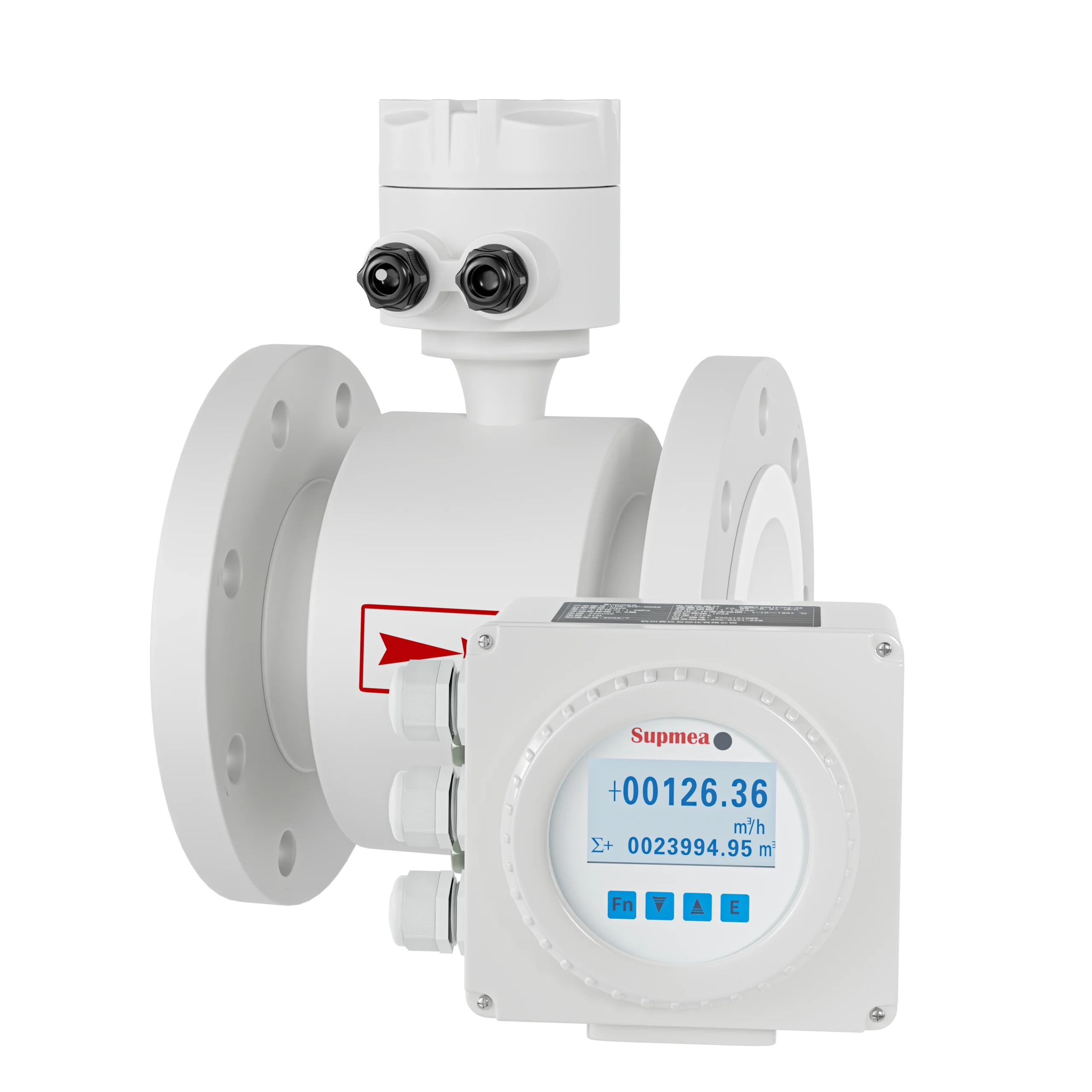

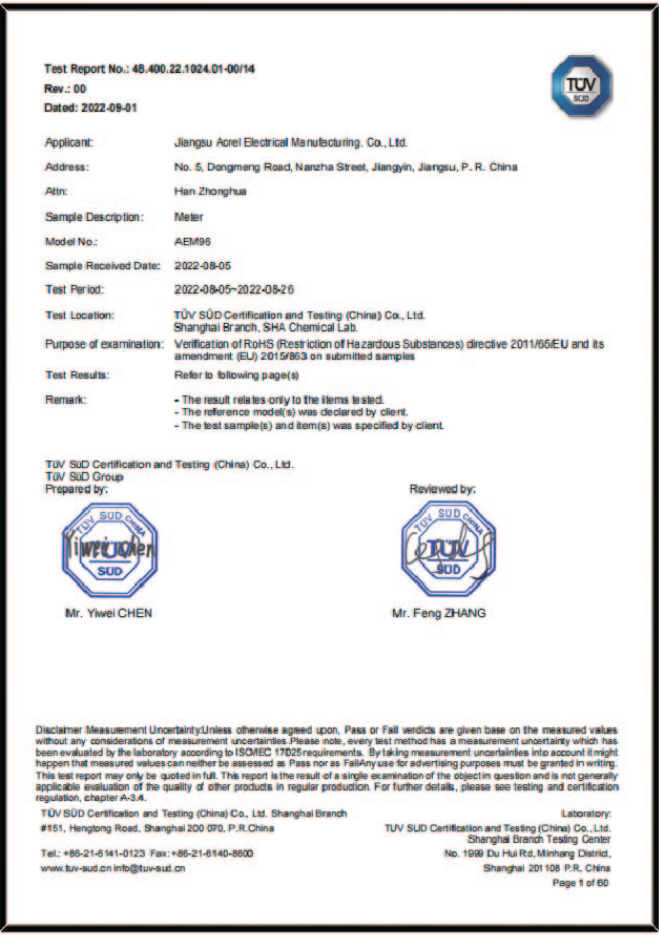

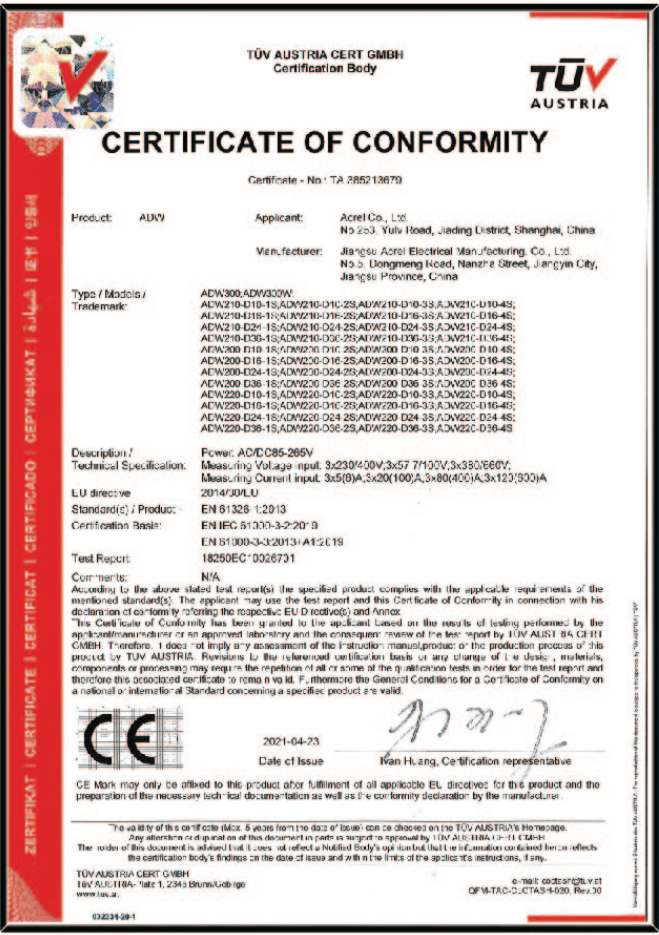

Selink Vietnam has been establishing a strong presence in the domestic market and is steadily expanding toward regional and international markets through its core business solutions, including: Smart CMMS (Computerized Maintenance Management System), Smart Factory solutions, Temperature and Humidity Monitoring Systems, Energy Monitoring Systems, and Intelligent Liquid Flow Monitoring Systems integrated via mobile applications and web platforms.

Learn more