COMPREHENSIVE ENERGY MONITORING & MANAGEMENT SYSTEM

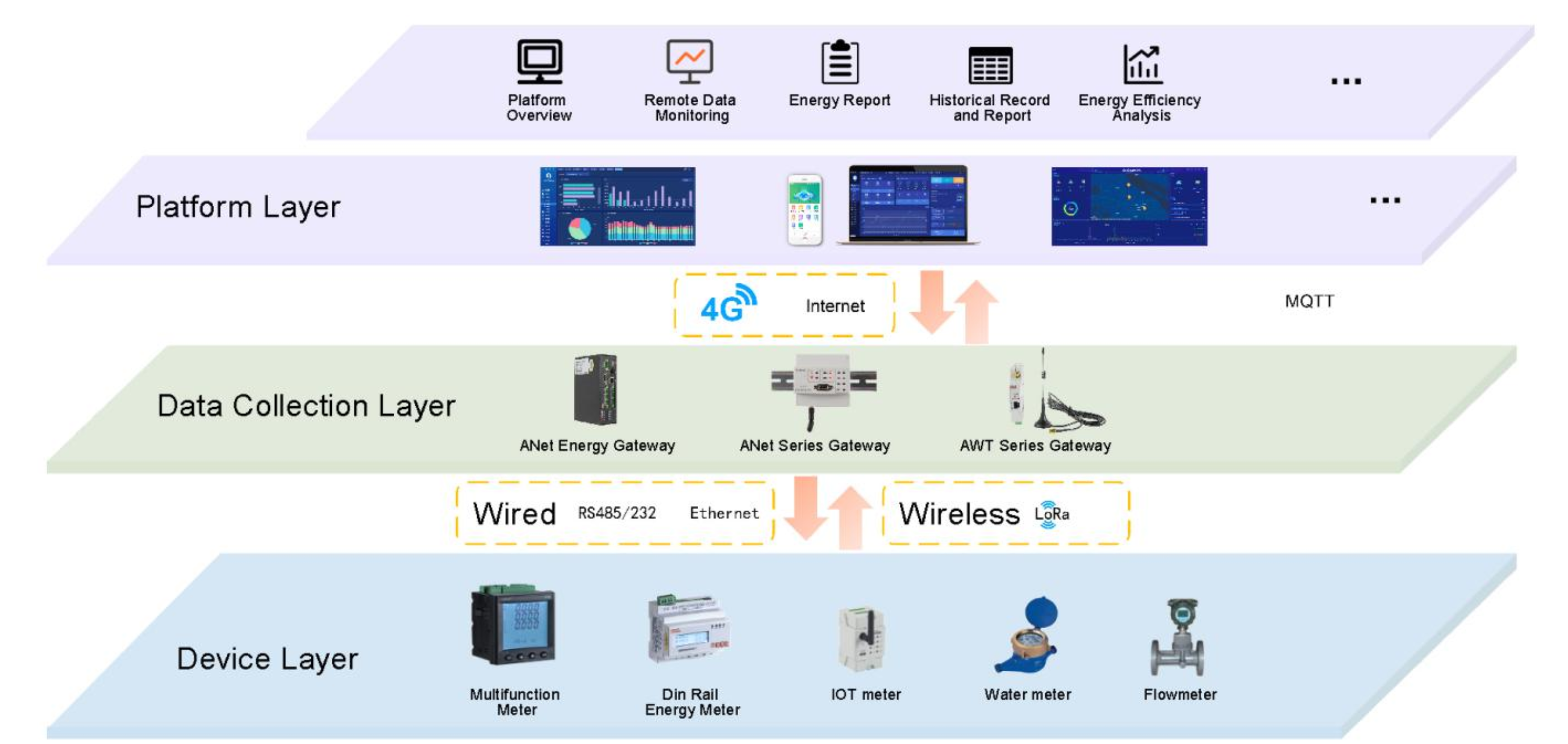

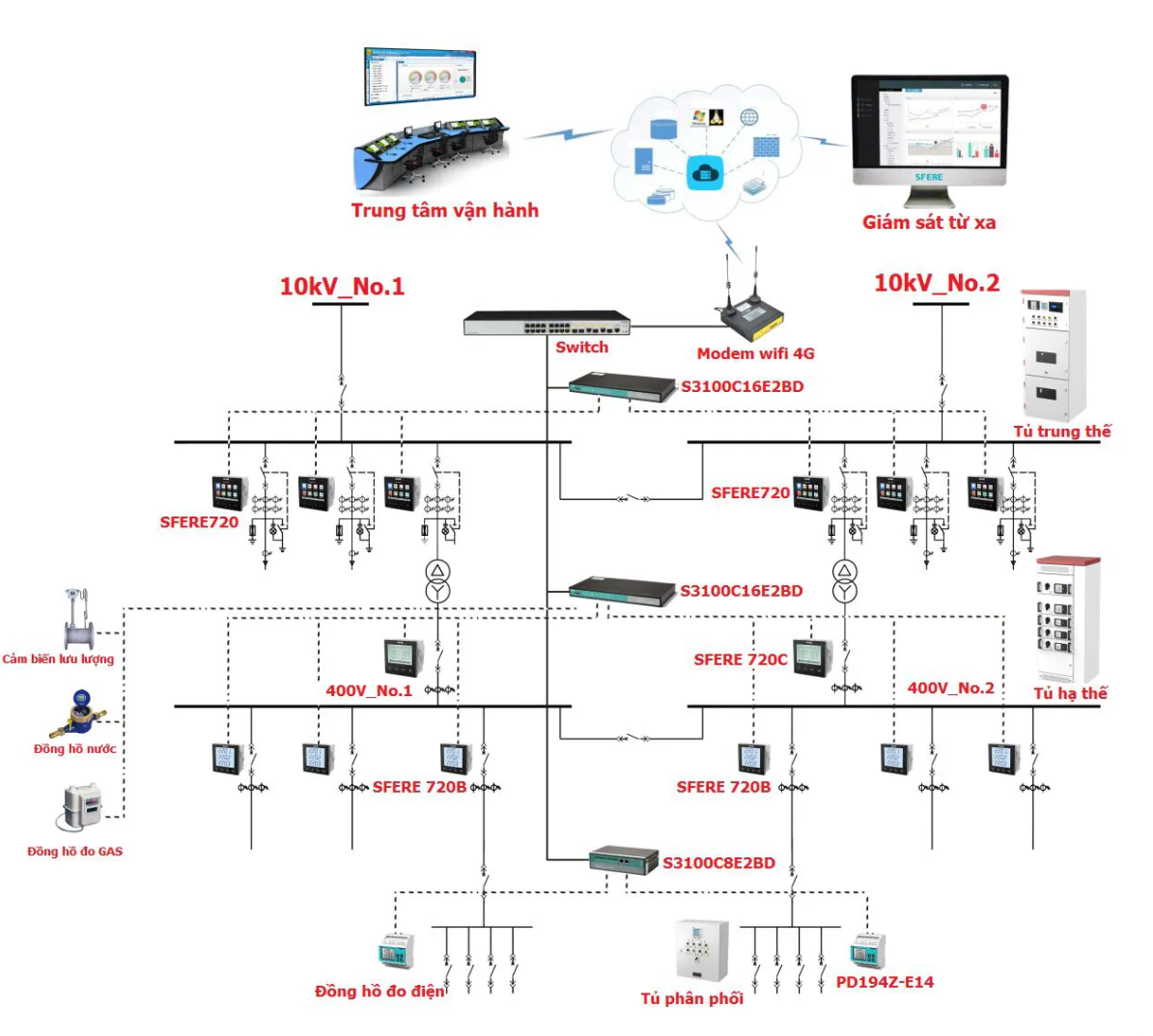

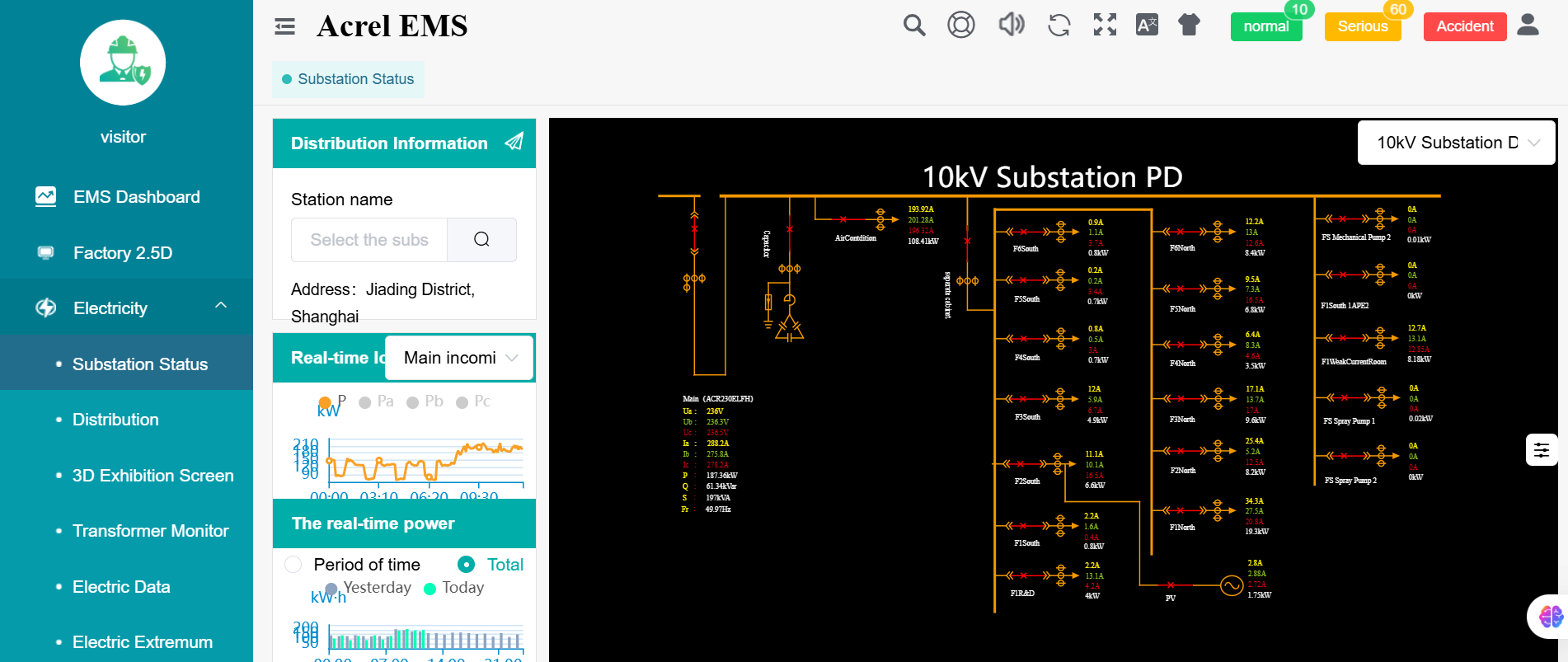

This is a comprehensive energy monitoring system for manufacturing plants. The system consists of multiple energy meters installed throughout the factory to monitor electrical parameters of production equipment groups. RS485 field signal converters transmit data to a high-speed Ethernet network, allowing all electrical parameters to be centralized at an industrial computer. This industrial computer runs SCADA software to support energy monitoring and statistical analysis across the plant. Thanks to the highly distributed architecture of SCADA software, authorized managers can remotely monitor the entire system via smartphones or laptops over the Internet.

1. SYSTEM ARCHITECTURE

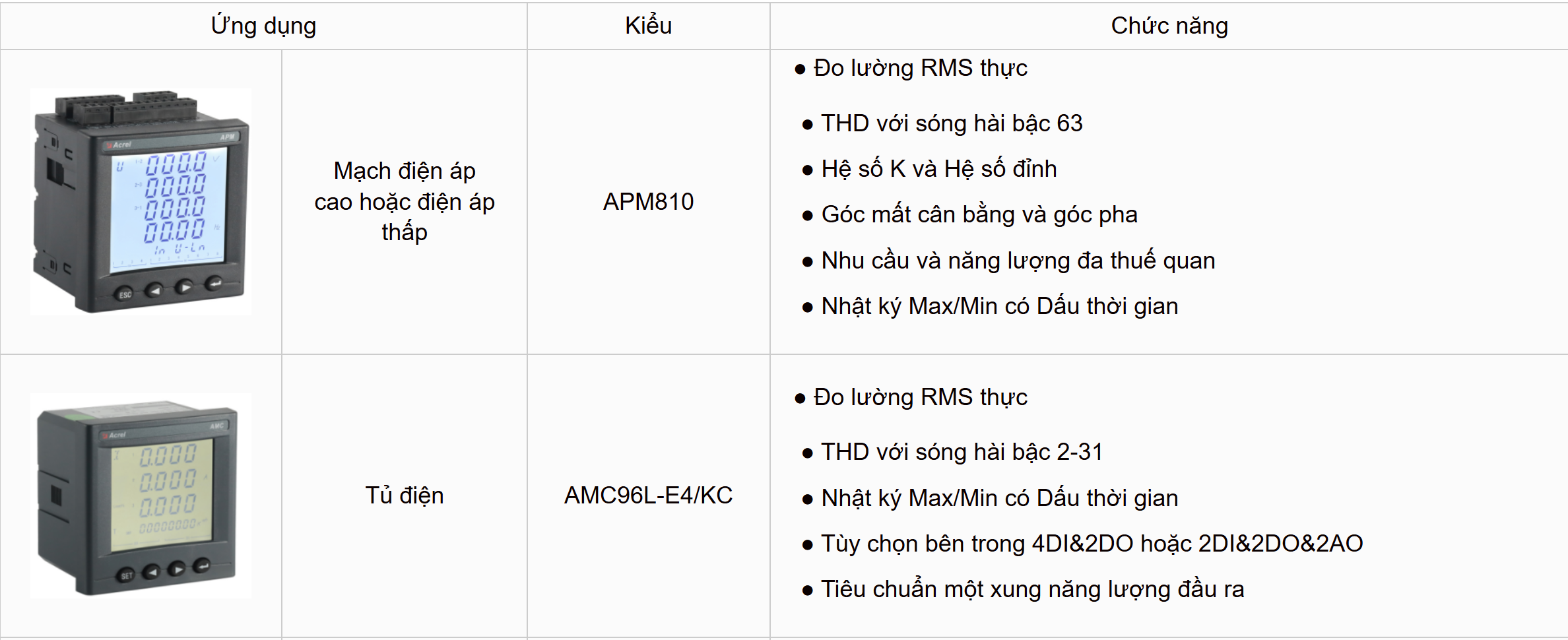

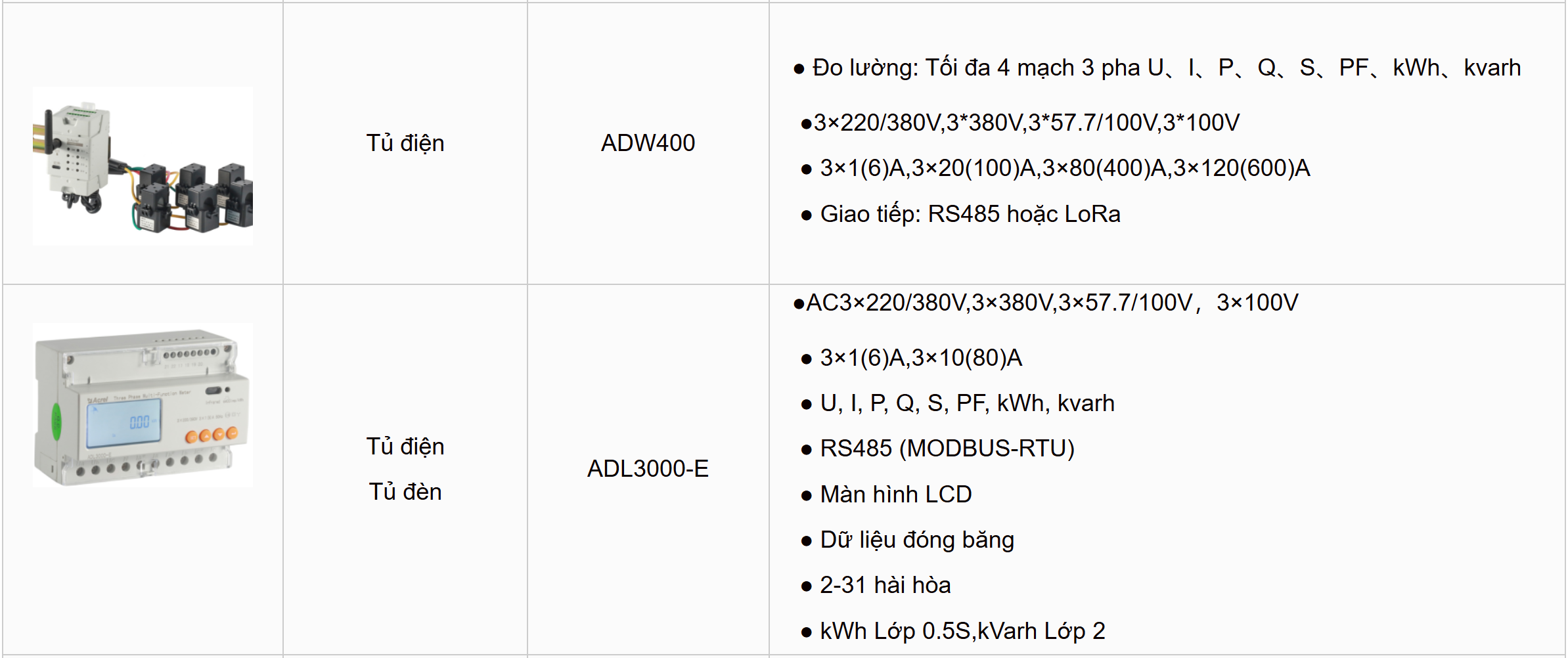

2. EQUIPMENT

3. FEATURES OF THE ENERGY MONITORING & MANAGEMENT SYSTEM

The proposed energy monitoring system provides the following functions:

-

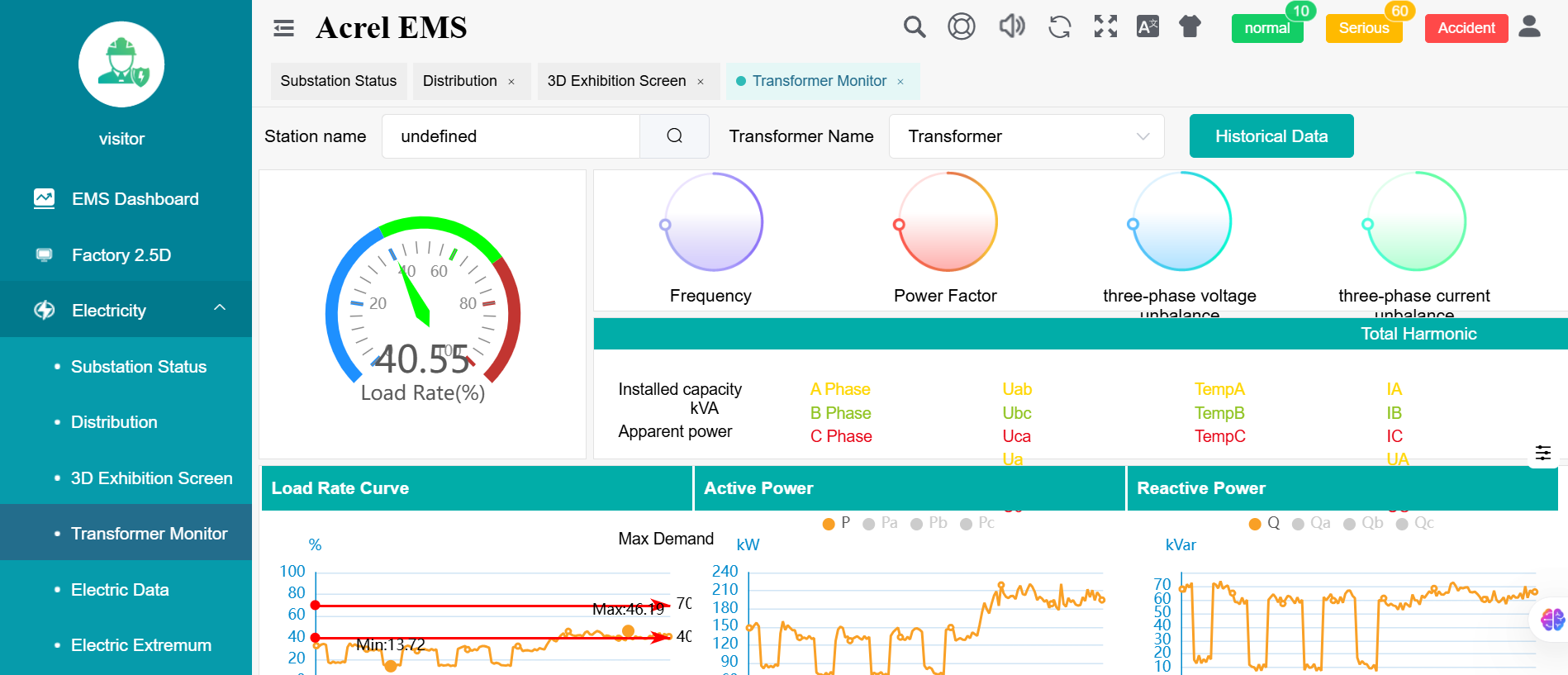

Displays all real-time electrical parameters of on-site machinery in the factory, including Voltage (U), Current (I), Power Factor (Cosφ), Active Power (P), Reactive Power (Q).

-

All parameters from energy meters are centralized and displayed on SCADA software running on an industrial computer.

-

Configurable alarm thresholds for conditions such as overload, phase loss, abnormal power factor, etc.

Alerts are triggered locally via warning lights and buzzers, via SMS using an integrated SMS modem, and via email when the industrial PC is connected to the Internet. -

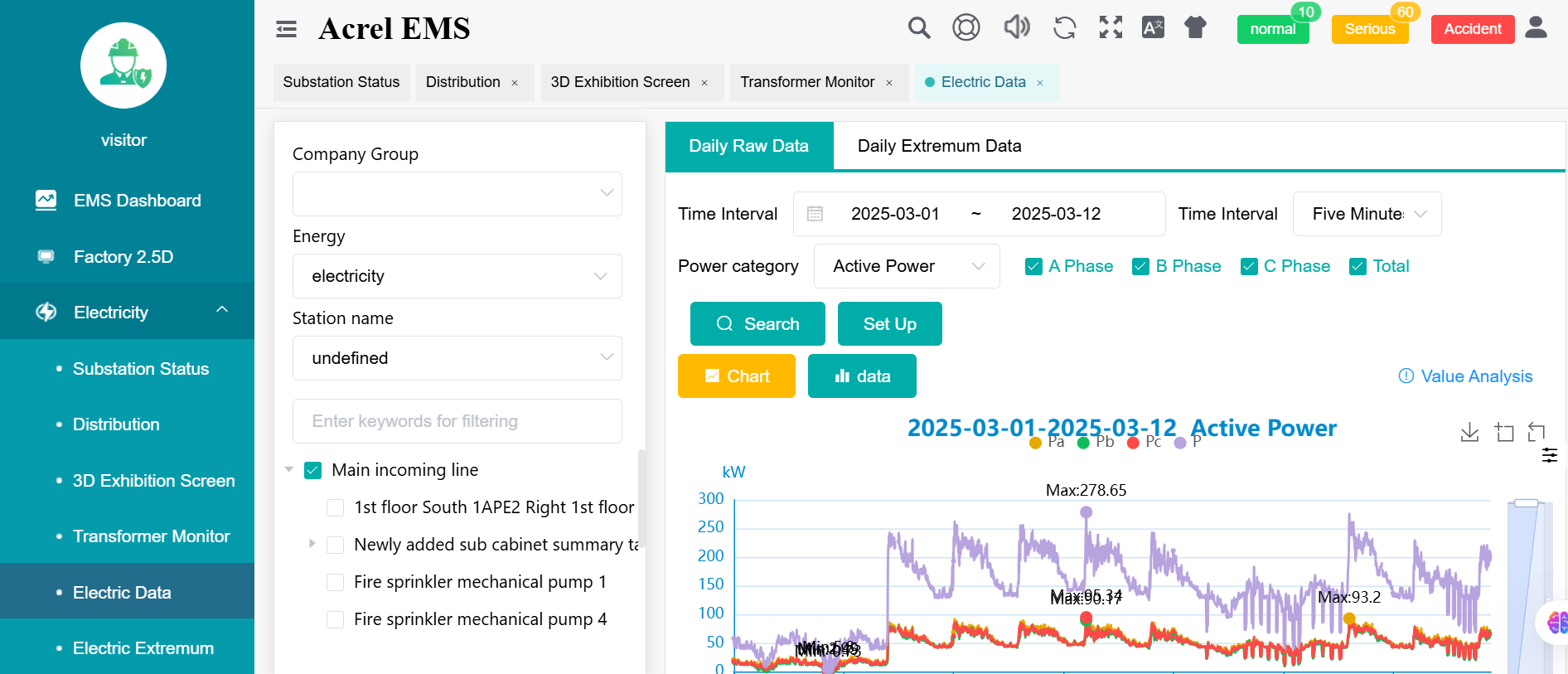

Real-time electrical parameters are visualized in numerical values and various graphical formats, and stored for reporting, analysis, statistics, and export to Excel files.

-

When Internet connectivity is available and remote monitoring is configured, authorized management levels can remotely monitor and export reports via web access using smartphones or laptops from anywhere.

A key characteristic of SCADA software used for Power Management Systems (PMS) is its ability to analyze and statistically process electrical consumption data, voltage, current, power factor, etc., to assess power quality.

The system supports equipment lifespan forecasting, calculates actual energy consumption over time, and estimates electricity costs payable to the power utility—allowing comparison and verification against official electricity bills.

4. BENEFITS OF THE ENERGY MONITORING & MANAGEMENT SYSTEM

-

Automation that replaces manual recording of electricity meter readings.

-

Significantly improves measurement accuracy across multiple energy meters.

-

Continuous 24/7 data collection for reporting, analysis, and alerting purposes.

-

Enables timely response to electrical incidents through alerts, helping protect equipment.

-

Forecasts grid power quality and equipment operating conditions, enabling proactive maintenance and reduced downtime.

-

Supports proactive planning and implementation of energy-saving solutions based on analytical reports.

-

Generates total energy consumption reports and corresponding electricity costs, serving as an objective tool to verify utility invoices.

-

Maintains optimal load levels, minimizing overloading or underutilization scenarios.

Contact Selink today for consultation on energy management systems and factory maintenance & automation solutions.