The Electrical Cabinet Busbar Temperature Monitoring Service is a specialized system designed to continuously monitor and alert temperature conditions at critical connection points—such as busbars, joints, and incoming/outgoing cables—inside medium-voltage and low-voltage electrical cabinets

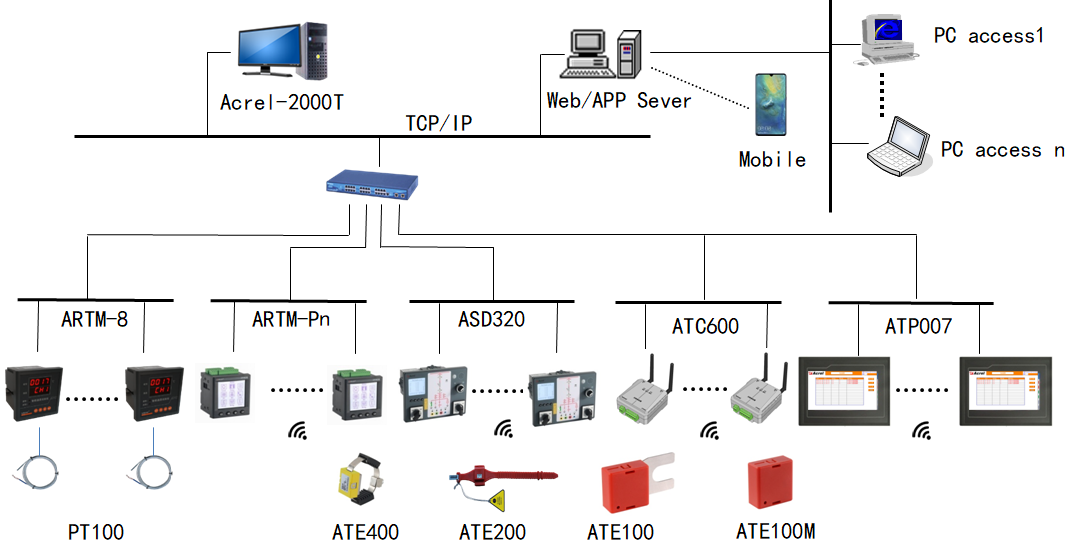

1. SYSTEM ARCHITECTURE

2. OPERATING PRINCIPLE

-

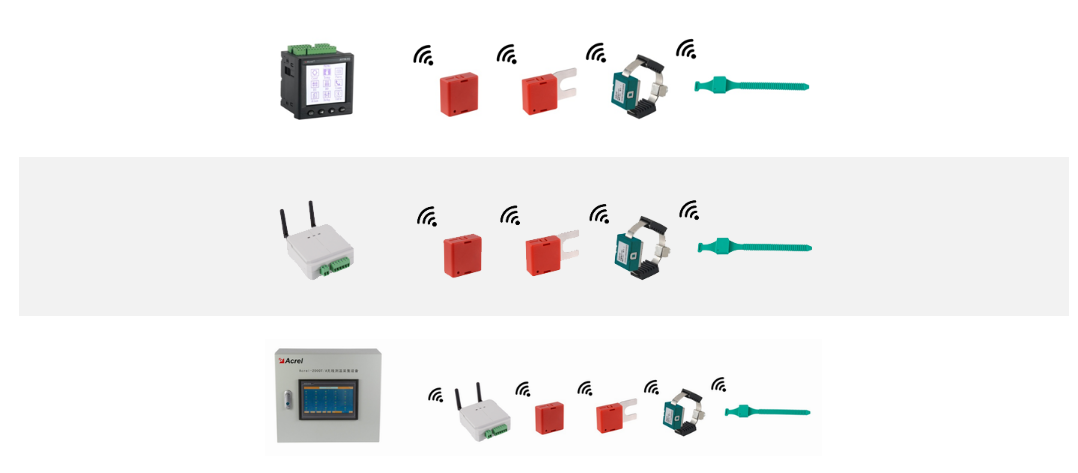

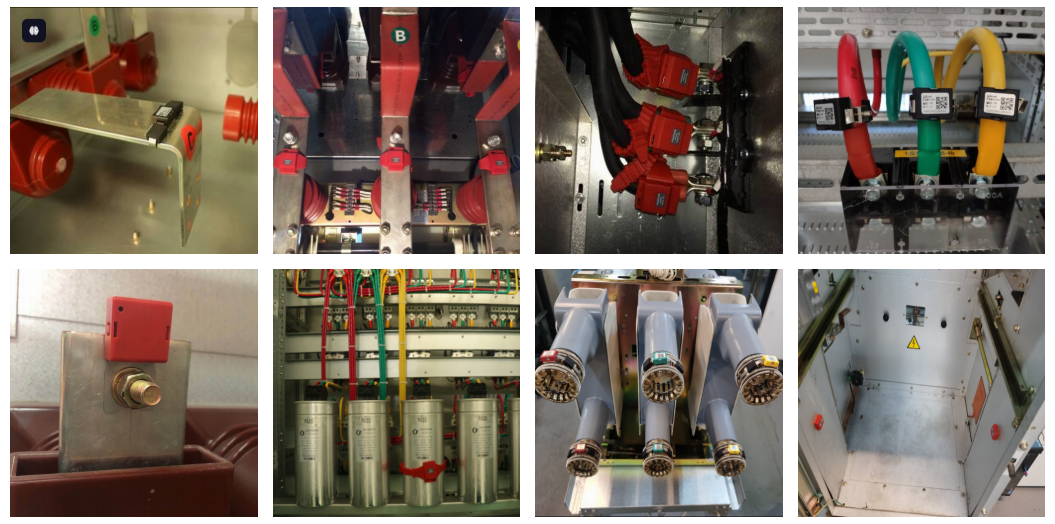

Monitoring Devices: Non-contact (infrared) or contact temperature sensors are installed at designated monitoring points.

-

Data Acquisition & Transmission System: Includes signal collectors, converters, and communication modules (e.g. Ethernet, RS485, or wireless transmission).

-

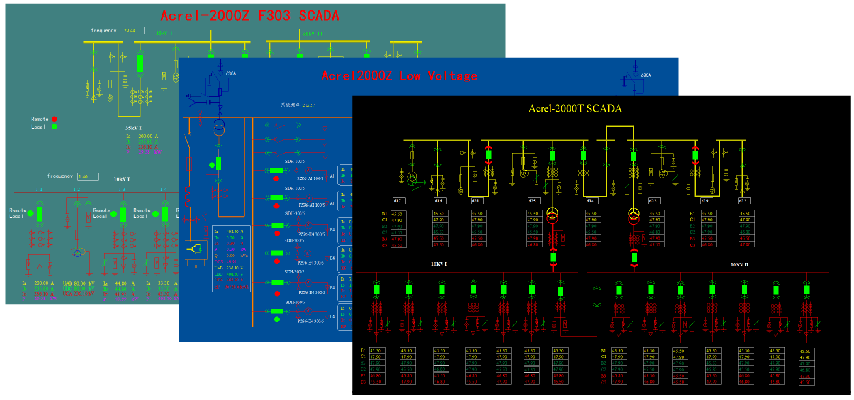

Display & Software System: On-site display panels, centralized monitoring software on local computers, or cloud-based monitoring platforms.

-

Alarm System: Integrated alarms via sound, indicator lights, SMS messages, emails, or mobile applications when temperature exceeds predefined thresholds.