SELINK CMMS & IOT – SMART MAINTENANCE MANAGEMENT

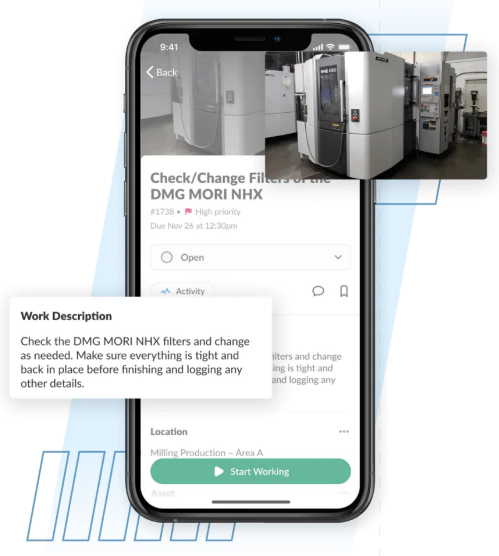

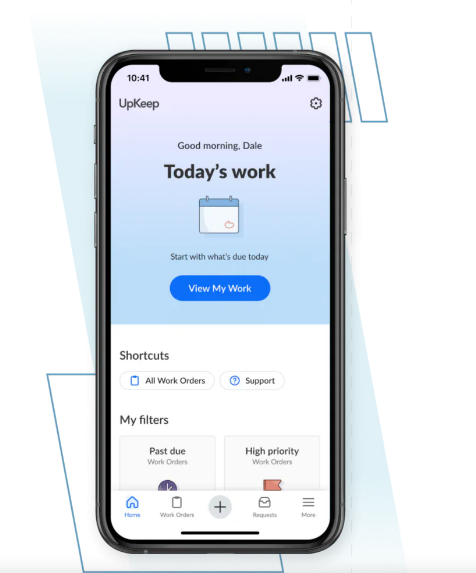

Selink’s Smart Maintenance Management solution is designed and developed for factory management teams and industrial maintenance engineers.

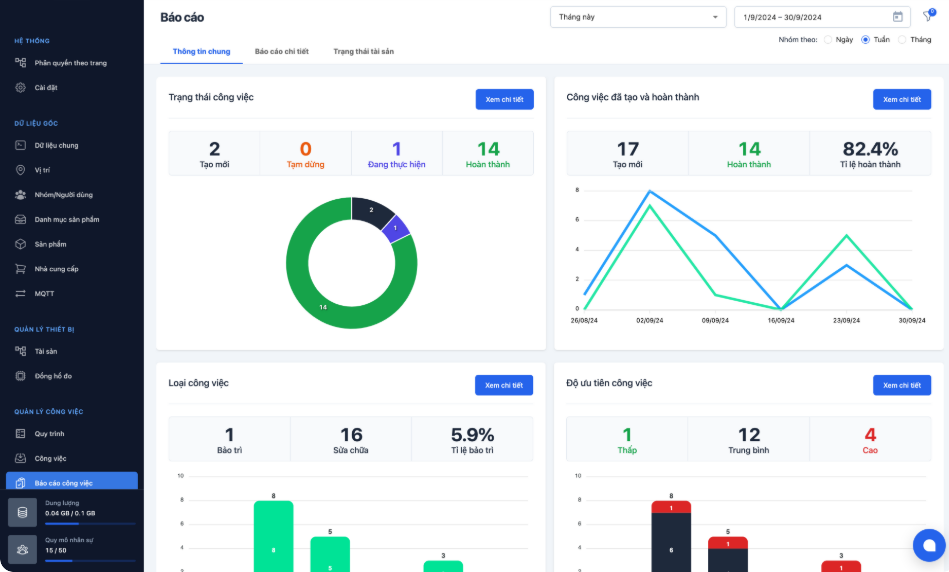

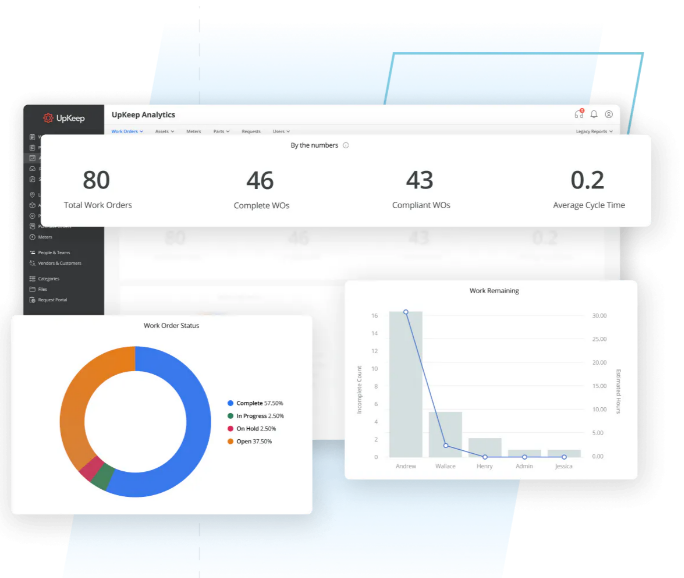

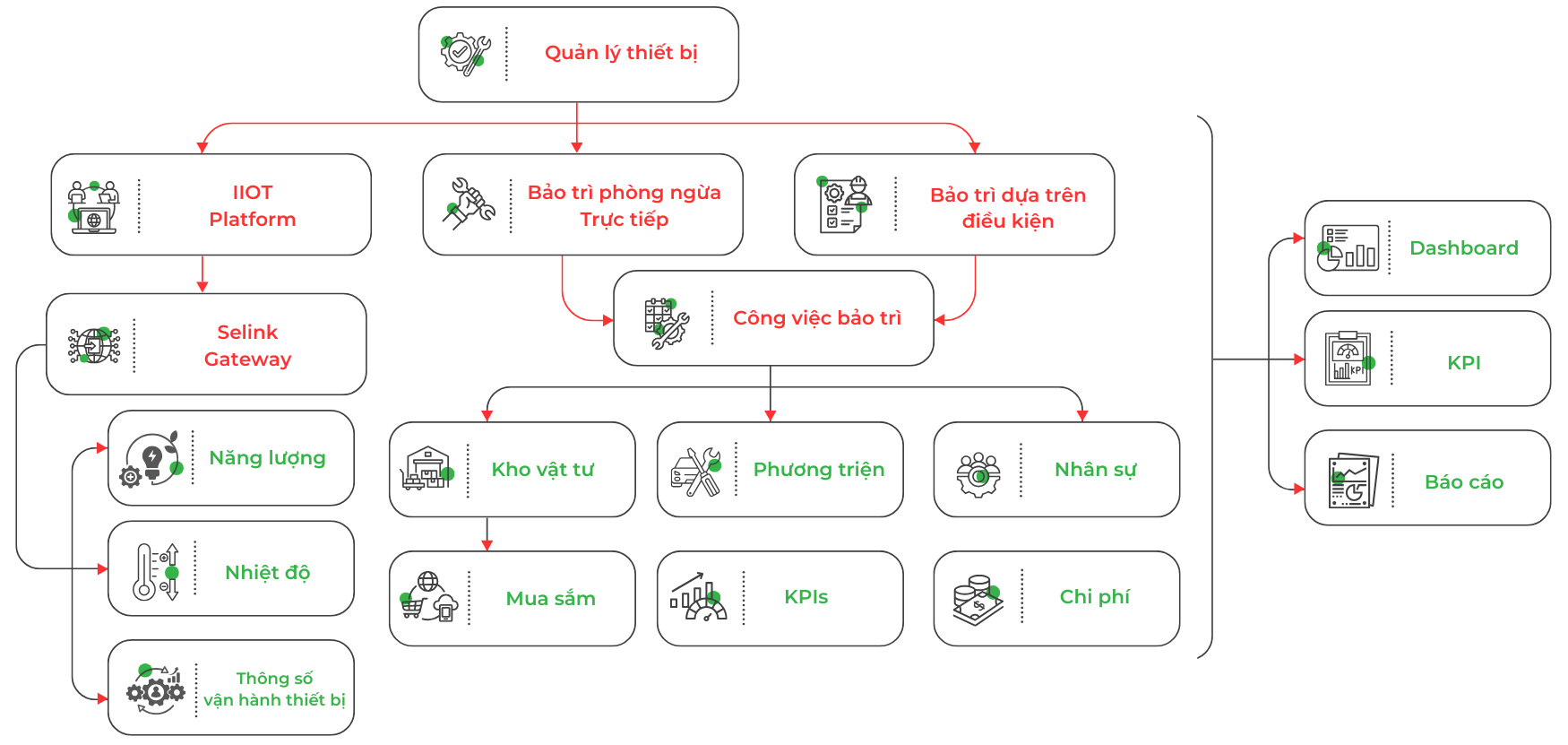

Equipment status, work orders, inventory, and full asset lifecycle information are all centrally controlled within the system.

With Selink’s Asset Maintenance Management Software, maintenance technicians are equipped with the tools they need to optimize productivity and operational efficiency, while seamlessly connecting critical production data with company-wide planning.

Contact Us Now

90%

Reduce the time technicians spend on job management and asset information searching

315%

Return on Investment (ROI)

25 BILION VND

Cost savings from reduced production downtime