SMART FACTORY: THE FUTURE OF INDUSTRIAL MANUFACTURING

In the era of digital transformation, the industrial sector is undergoing a profound revolution with the emergence of the Smart Factory. This is not merely a technology trend but an optimal solution that helps enterprises increase productivity, reduce costs, and enhance competitiveness.

So, what is a Smart Factory, and what benefits does it bring? Let’s explore in the article below.

1. THE CONCEPT OF A SMART FACTORY

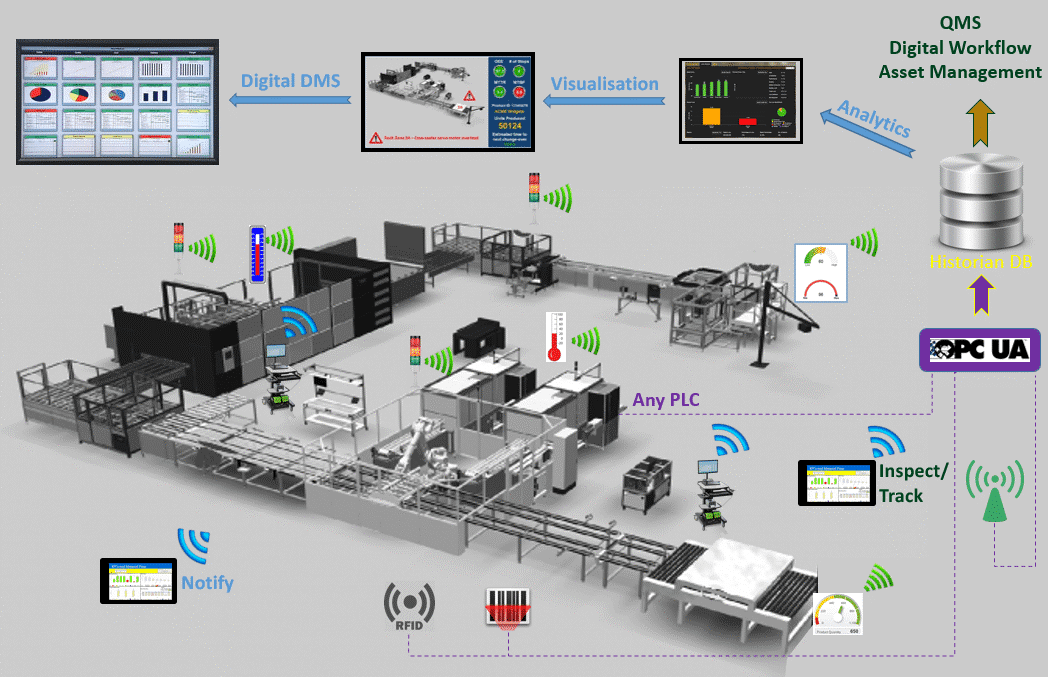

A Smart Factory is a manufacturing model that applies advanced technologies such as the Internet of Things (IoT), Artificial Intelligence (AI), Big Data, industrial robots, and cloud computing to connect the entire production process.

From raw material management and machine operation to quality control and logistics, all activities are digitized, automated, and optimized in real time.

2. CORE SERVICES & SOLUTIONS OF A SMART FACTORY

a. Automation & Smart Robotics

Industrial robots and Automated Guided Vehicles (AGVs) replace human labor in hazardous or repetitive tasks.

Smart control systems continuously monitor and adjust production processes, ensuring high accuracy.

b. Data Analytics & AI

Collects and analyzes data from IoT sensors to predict maintenance needs (predictive maintenance) and optimize machine performance.

AI supports real-time, data-driven decision-making, such as adjusting production schedules or managing inventory.

c. Digital Twin

Creates virtual replicas of factories to simulate and test processes before real-world implementation, minimizing risks and reducing trial-and-error costs.

d. Smart Energy Management

Systems monitor energy consumption and recommend energy-saving solutions, helping enterprises move toward low-carbon and sustainable operations.

e. Supply Chain Connectivity

Integrates Blockchain and ERP technologies to enhance transparency across the supply chain—from raw materials to product distribution.

f. Cybersecurity & Data Protection

Solutions that protect factory data from cyber threats, ensuring safe, secure, and continuous system operations.

3. BENEFITS OF IMPLEMENTING A SMART FACTORY

-

Increased Productivity: Automation enables 24/7 production and reduces downtime.

-

Cost Savings: Minimizes material waste and optimizes labor and energy usage.

-

Flexibility: Easily adjusts production scale based on market demand.

-

Improved Quality: Automated inspection technologies detect defects quickly.

-

Sustainable Development: Reduces resource consumption and environmental impact.