SMART OPERATIONAL PARAMETER MONITORING SOLUTION – OPTIMIZING ENTERPRISE PRODUCTION OPERATIONS

This is a comprehensive energy and operational monitoring system for manufacturing plants.

The system includes multiple energy meters installed throughout the factory to monitor electrical parameters of production equipment clusters. RS485 field signal converters transform data into a high-speed Ethernet network, enabling electrical parameters to be centralized at an industrial computer. This industrial computer runs SCADA software to support energy monitoring and statistical analysis across the factory. Thanks to the distributed architecture of SCADA software, authorized managers can remotely monitor the entire system via smartphones or laptops over the Internet.

In the context of modern industry, optimizing production efficiency is one of the key factors determining business success. Operational parameter monitoring software was developed to meet this demand, helping enterprises monitor and optimize production processes within the Manufacturing Execution System (MES). Below are the key features and outstanding advantages of the Operational Parameter Monitoring Software.

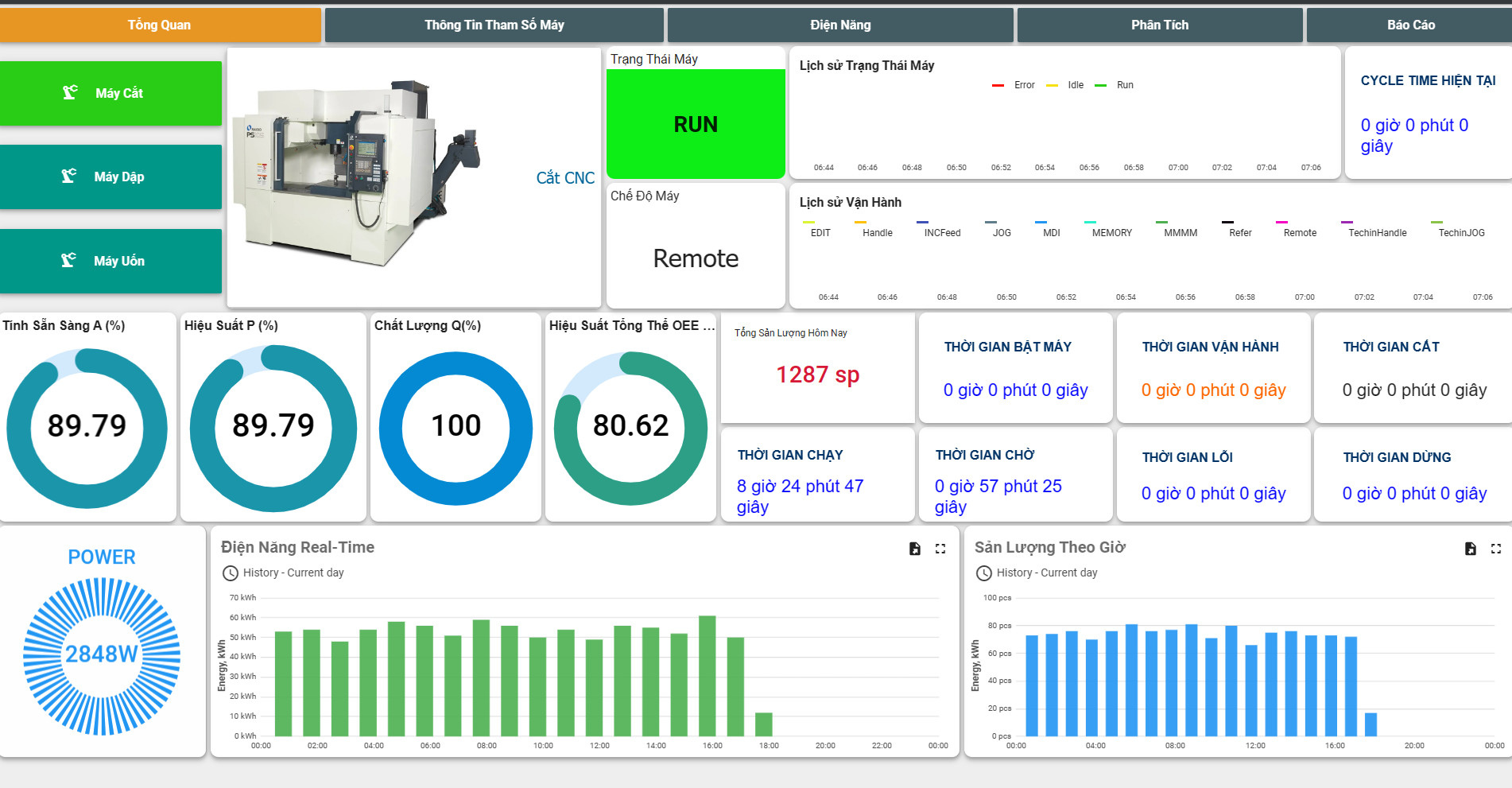

1. COMPREHENSIVE PRODUCTION EFFICIENCY MONITORING

The Operational Parameter Monitoring Software provides powerful tools to monitor the efficiency of production equipment utilization.

Data is collected in real time from machines and equipment across the production line, allowing enterprises to easily track key indicators such as:

-

Availability: Measures actual equipment operating time compared to planned operating time.

-

Performance: Compares actual production speed with theoretical production speed.

-

Quality: Evaluates the ratio of qualified products to total products produced.

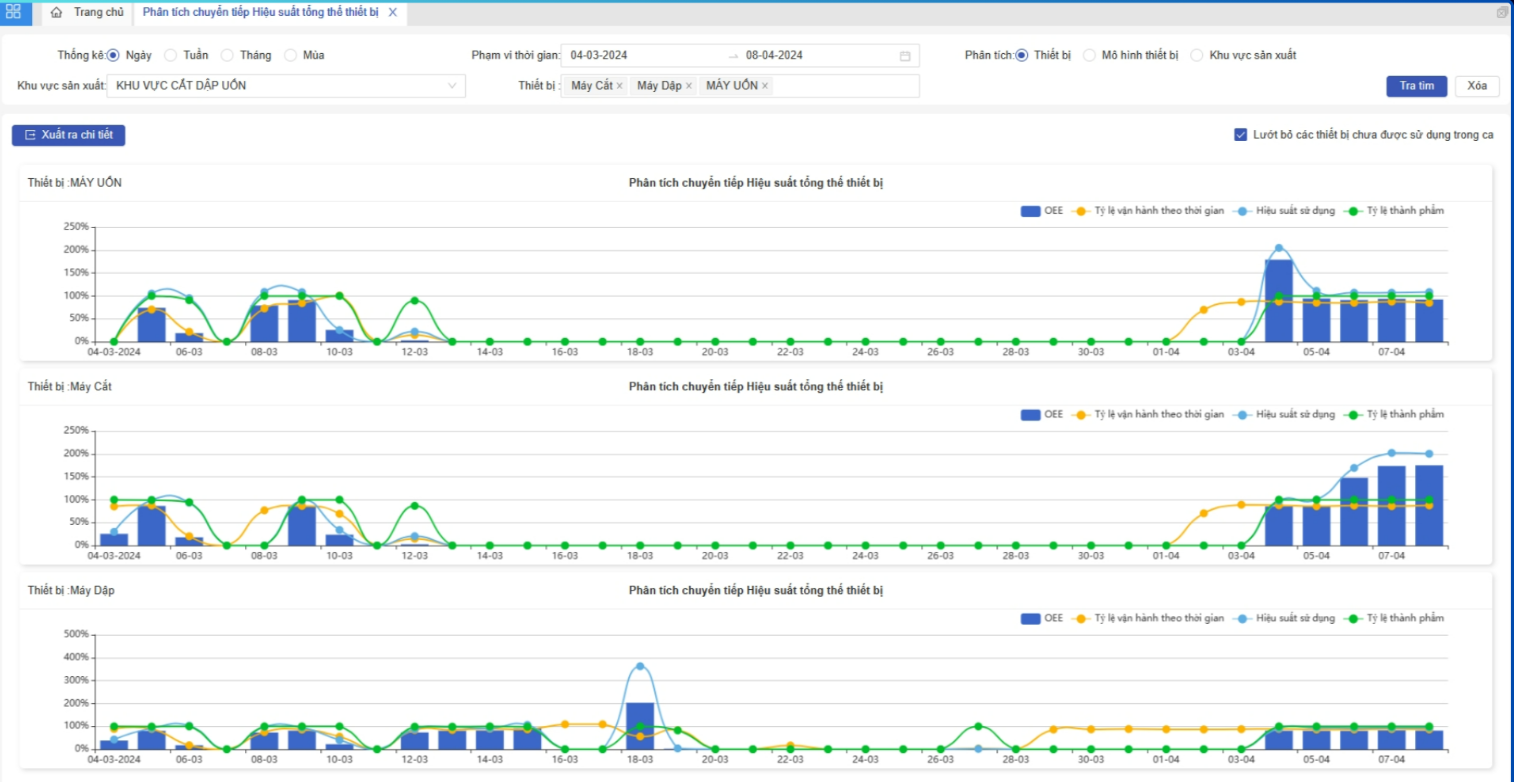

2. DETAILED ANALYSIS & REPORTING

The Operational Parameter Monitoring Software not only collects data but also provides powerful analytical tools.

Detailed reports help enterprises identify the root causes of issues occurring during production and propose effective corrective actions.

Key analytical features include:

-

Real-Time Reporting:

Enterprises can view reports as production is taking place, enabling rapid response to emerging issues. -

Root Cause Analysis:

Helps identify primary causes of waste and production incidents. -

Time-Based Data Comparison:

Allows comparison of production performance across different periods to evaluate implemented improvements.

3. PRODUCTION PROCESS OPTIMIZATION

One of the most outstanding advantages of the Operational Parameter Monitoring Software is its ability to optimize production processes.

Based on analytical data, the software recommends process improvement measures to help enterprises:

-

Minimize Downtime:

Increase equipment availability through preventive maintenance strategies. -

Improve Production Efficiency:

Adjust production speeds to achieve optimal performance while maintaining product quality. -

Enhance Product Quality:

Reduce defect rates by optimizing quality control processes.

4. EASY INTEGRATION WITH MES SYSTEMS

The Operational Parameter Monitoring Software is designed for seamless integration with existing MES systems.

This ensures continuity in production processes while maximizing the use of available data to enhance operational monitoring.

-

Data Integration:

Synchronizes data from MES systems and the monitoring software to create a comprehensive view of production operations. -

Compatibility with Multiple Equipment Types:

The software can connect to a wide range of machines and equipment across production lines, ensuring system flexibility and scalability.

5. STRATEGIC BENEFITS FOR ENTERPRISES

Implementing Operational Parameter Monitoring Software delivers not only immediate benefits in monitoring and optimization but also long-term strategic value:

-

Enhanced Competitiveness:

Produce higher-quality products in shorter timeframes, strengthening market competitiveness. -

Cost Savings:

Reduce resource waste and optimize equipment utilization to lower operating costs. -

Decision Support:

Provide accurate, timely data to support strategic decisions based on real operational insights.

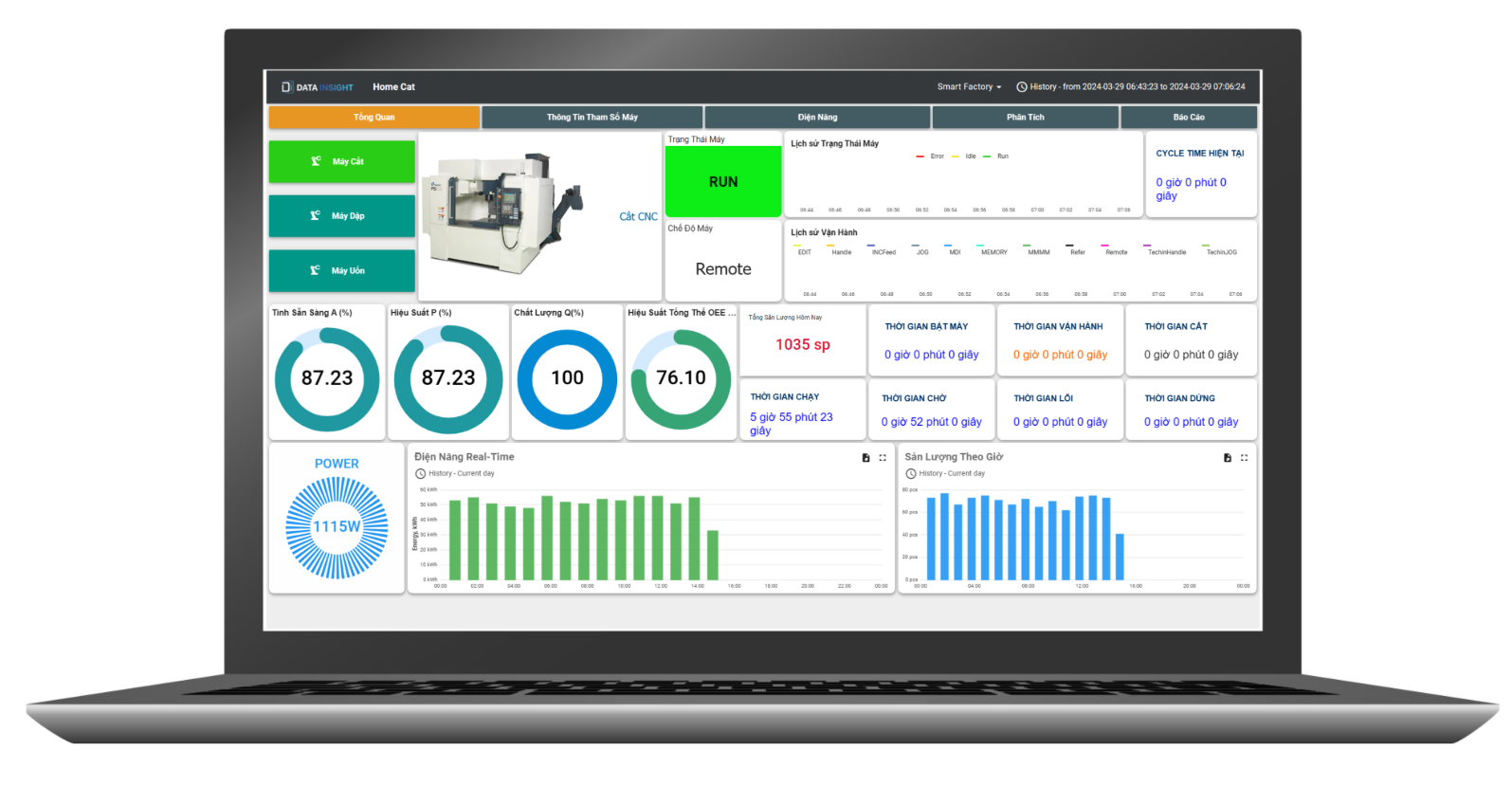

6. CONVENIENT REMOTE CONTROL INTERFACE

The Operational Parameter Monitoring Software features a modern, user-friendly interface that allows enterprises to monitor and control systems remotely—an essential capability for effective production management in modern industrial environments.

-

Intuitive Interface:

Visual dashboards with charts, tables, and reports allow users to track key operational indicators without requiring deep technical expertise. -

Remote Access:

Supports access via Internet-connected devices such as computers, tablets, and smartphones, enabling management anytime, anywhere. -

Instant Notifications:

Provides real-time alerts when incidents or abnormal fluctuations occur, allowing timely decisions to minimize risks and losses. -

Flexible Adjustments:

Remote control capabilities enable immediate adjustments to production processes without being physically present at the factory. -

High Security:

Advanced security measures protect enterprise data and ensure that only authorized users can access critical system functions.